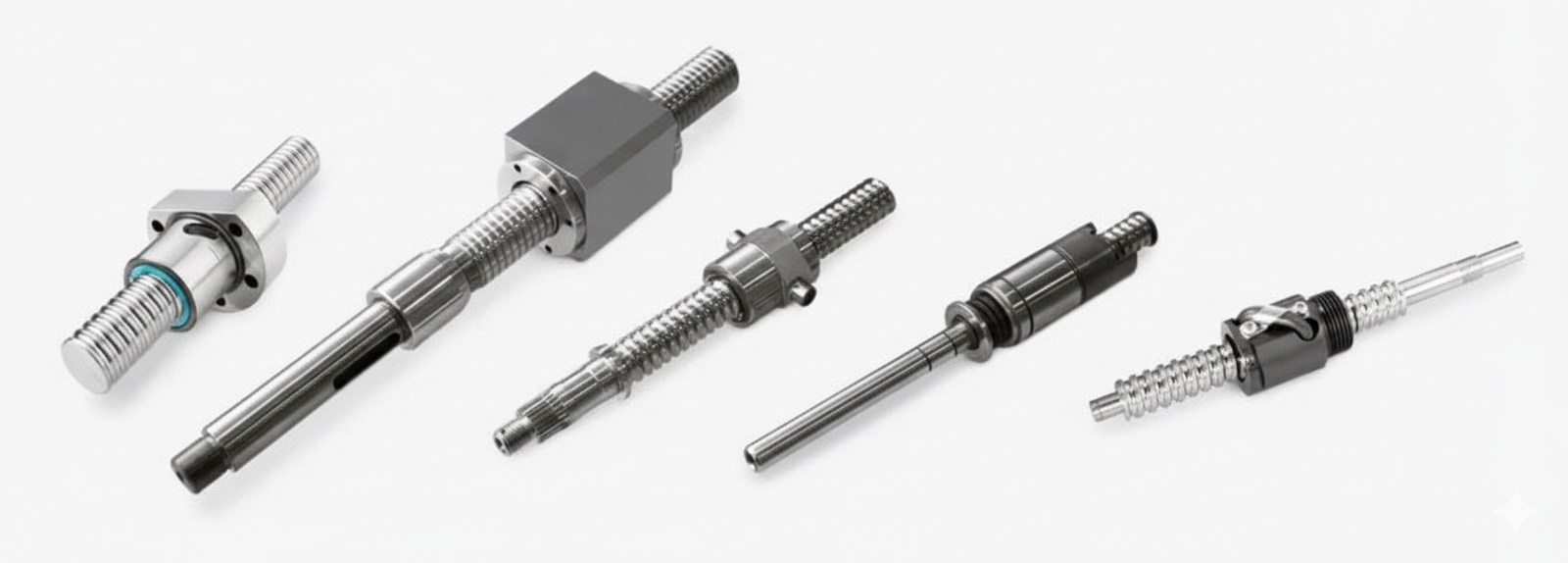

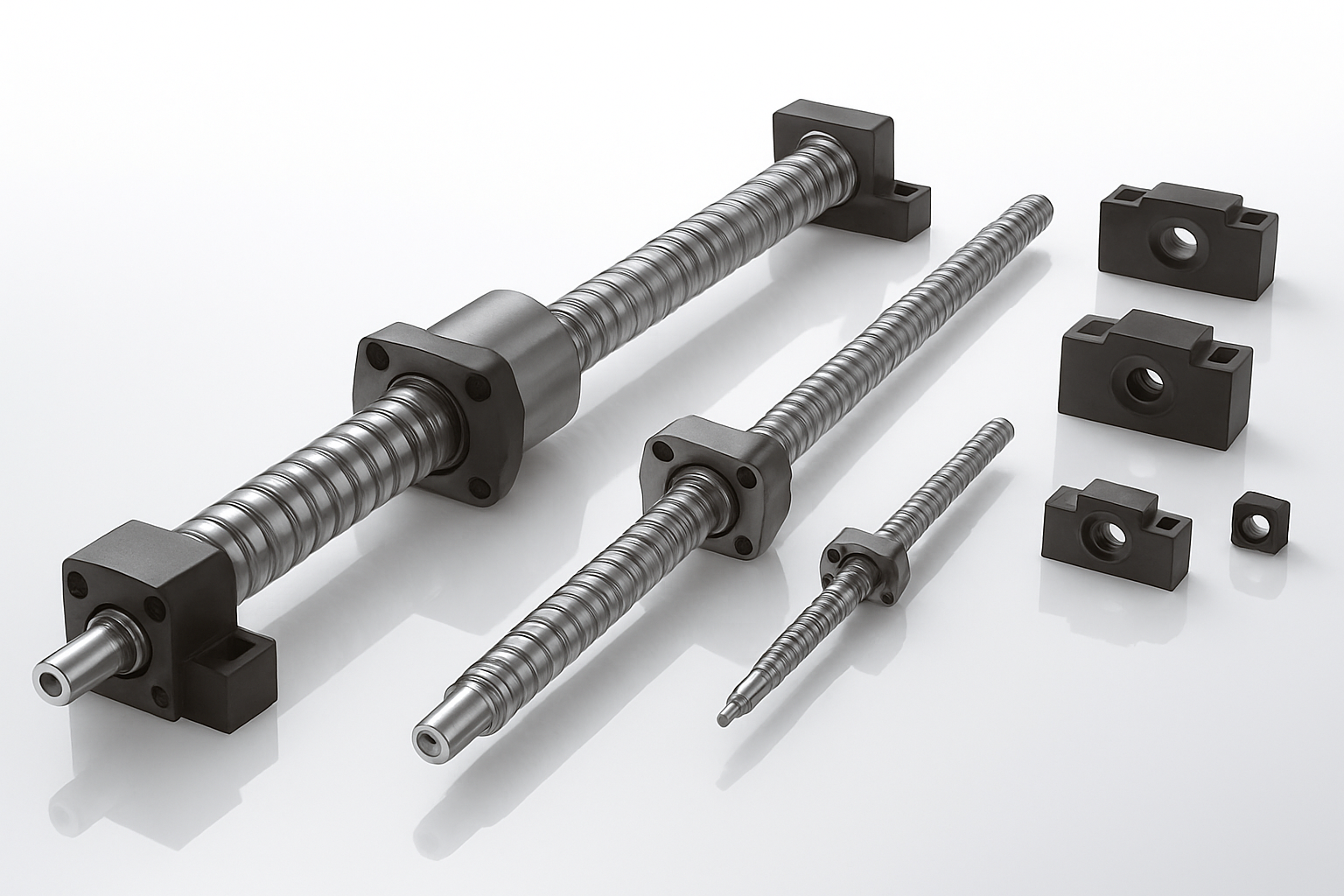

Ball screw repairing / reconditioning

We repair and recondition the process of

restoring the worn or damaged ball screw and assemble it to its original working

condition, rather than replacing it with the one. Our service involves several key steps –

such as inspection and dissemination, cleaning of all parts, regrind and polish, replace

the

ball bearings with new ones, lubricate and reassemble and at the end test the ball

screws for accuracy and smooth movement.